D1041 Restoration Report:

September 2014 - February 2015

Time for another recap of progress since the last report. The workrate often slows up during the coldest months and this Winter is no exception. The locos in the shed hold the temperature down meaning it is usually colder inside than out. However, work continues none the less, even if it is at a slower pace.

September 2014

The B-end cab continues to see modifications and improvements and is now sporting

a nicely refurbished AWS sunflower which has been wired in. With no more wires to

pull through, the cab floor is being refitted and any remaining equipment below

modified and upgraded as necessary. All of the work at B-end should make the A-end

rebuild a much smoother process altogether.

Refurbished AWS 'Sunflower' head in situ and wiring terminated to the rear

B-end cab flooring, with air tank visible left, 40v to 12v voltage converter right below floor level

Refurbished AWS 'Sunflower' head in situ and wiring terminated to the rear

B-end cab flooring, with air tank visible left, 40v to 12v voltage converter right below floor level

For all the beautiful lines and great looks, Thousands, like many locos, also have some things in fairly daft places, one such item is the cab and marker light switch panel, located down in the bottom left corner of the desk by the driver's left shin.

As the termination of wiring in the cab continues to progress, this was another item ticked off as done. Strangely, or perhaps not really, a conversation on Facebook delved into the perils of various types of cable ties, but we have this covered ..

The ties used on D1041 for all the loco and desk wiring have a small metal insert in the head of the tie wrap; the locking side is made up of tiny little domes rather than a serrated edge, so they don't damage insulation and never fail to grip properly. They don't make a sound when you pull them tight which can take some getting used to initially!

Aside from all things electrical, one of the main A-End coolant pipes had welding repairs thanks to Jonathan Valentine for his excellent work down at Buckley Wells Carriage and Wagon Works. It's great when everyone helps. Currently in 'Thomas' undercoat blue, a coat of 'coolant' french blue will be applied in due course!

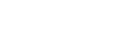

B-end cab switch panel all terminated rear (left), front (right) and A-end coolant pipe

October-November 2014

Inevitably, with a project as large as D1041, when stripping stuff out, phrases like "oh just rip it out, chisel, snap or drill the bolt heads off, we can always drill and tap it later" were often heard.To be fair, sometimes there just isn't another way, with long situated and/or rusty bolts often extremely reluctant, some turn then snap and rarely one comes out ok! The guys involved with D1013 and D1062 are familiar with all of the above .. and the below ...

So, guess what? ... yep now I'm drilling and tapping a million and one bolt holes out. Think I'm going to end up with vibration sickness and needing some more 2BA and 0BA taps!

The AWS equipment in B-end cab has been completely overhauled and rewired ready for commissioning. Located by the drivers seat, missing components were sourced from the BHG's old storage warehouse in Bolton and overhauled including the bell, change end switch, Baldwin EP valve and pneumatic horn. Missing pipework and conduit has been made and fitted.

The pneumatic horn has also been overhauled, however the modern electronic horn which works in conjunction with TPWS change end cards has also been fitted and wired. Well, you never know!

Left, the 'AWS Corner' of B-end cab, below the drivers window, the cab switch panel referred to earlier also visible and right, 40v to 12v voltage converter below B-end floor along with newly fitted sander air isolating cock

AWS relay box wiring all re-terminated with nylon PIDG crimps

Some original AWS wiring to the other cab was left in place after passing extensive megger testing to prove ok. The ends were re-terminated with nylon PIDG (Plastic Insulation Diamond Grip) crimps as the originals were starting to fail.

The 40v to 12v voltage converter has been refitted beneath B-end cab floor following testing and repair to the dropping resistor network. A new sander air supply isolating cock has also been fitted. All isolating cocks in the air and brake system are being replaced with modern valves as part of the systems overhaul which is being carried out alongside the rewiring.

December 2014-February 2015

Brand new covering material has been sourced for the desks in the form of Formica Colorcore and the fiddly cutting was underway during early December, it will look great, but is also a complex job in its own right.

B-end cab desk with Formica covering being cut, have we missed anything?

Elsewhere in the loco, the rewiring of the engine room bulkhead lighting is progressing well with Stephen and Andrew working away when time permits. Sometimes lots gets done, sometimes it's a battle feeding the plastic 'fish' along 60+ feet of conduit, all good fun!

D1041 Mainline Outing!

Classmate D1015 Western Champion has often run as former classmates on the mainline over the years and, on Saturday 13th December 2014, D1041 was the featured loco on one side of D1015 for the DTG's The Canterbury Champion railtour. Prince was depicted in Maroon with full yellow ends. See the tour report and photos at the DTG Website.Contrary to the report on page 87 of January's Railway Magazine, which reports D1015 running as ".. scrapped classmate No.D1041 Western Prince", we can confirm Prince wasn't, hasn't been nor is intended to be, scrapped! (thanks to Steve Hawes)

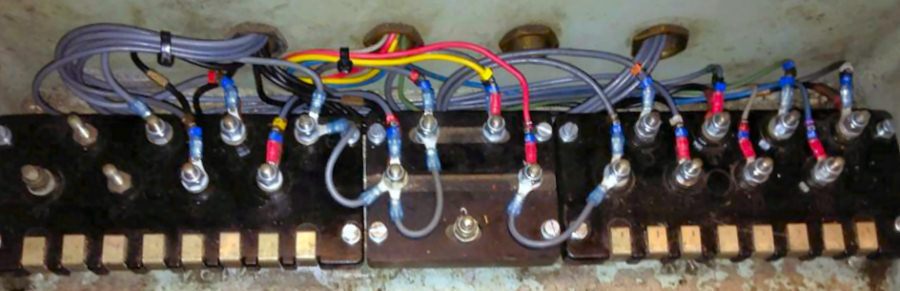

Stephen has also been progressing the A-end power frame with new termination bars being fitted. These still require final fixing and labelling before the crimping and attaching begins in earnest. There is no immediate rush with this as the A-end cab still requires a good deal of welding before any wiring can proceed.

Left, new termination blocks attached to A-end power frame

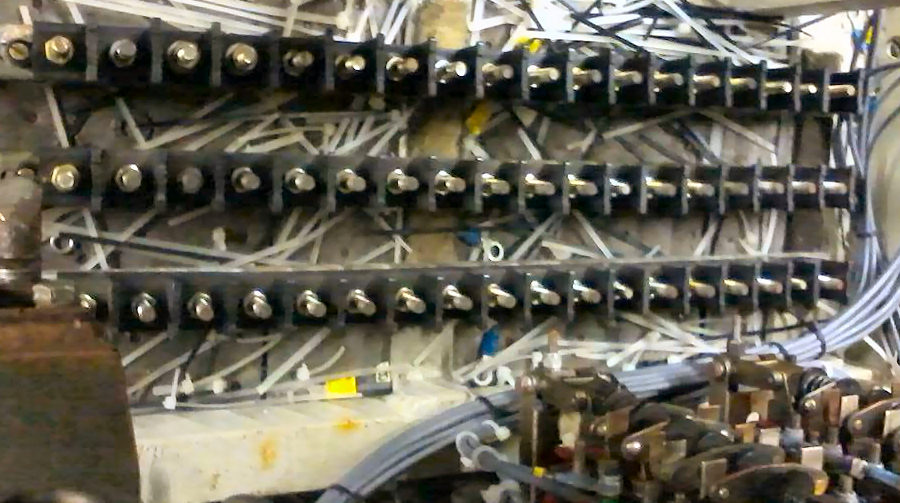

Wiring diagrams documenting the updates and modifications made to D1041

Whilst not working directly on the loco, a period of sickness meant was able to lock myself in my office and finally start putting my brain to use on the schematics for the finished D1041. Quite a bit has changed so it's important to document it with applicable drawings for the loco including PCR and DSD speed switch modifications, to name just two.

As mentioned earlier in the report, progress has slowed over the winter months plus life itself gets 'in the way' from time to time with changes of job, university, families and children to consider. All of that said, the team will be back in action this year progressing the welding repairs to A-End cab plus replating both front ends so Prince looks like a Western once again.

Thanks for reading. Please help the project with a donation if you can.

Regards

Matt Lindley