D1041 General Report:

Part 1: Sept 2013 -

April 2014

After a longer than anticipated gap, its time to recap what has been going on over the last 11 months! 2014 has been exceptionally busy and some of the Western Prince team were deployed to help with Class 14, D9537 which was turned round in time for the 14s@50 celebration.

The following is a digest of what has been going on with D1041 between September 2013 and April 2014.

September - December 2013

With a project as large as D1041, you have to take the small achievements as victories. Little things such as cleaning up the engine room treadplates for A-end, meaning the these can all be re-fitted as the control wiring in the engine rooms is now in place. It was only the other Month we were cleaning all the empty conduits.During 2013 the Facebook Group "All our yesterdays - Bashing Times" featured appeals from various loco groups and D1041 was selected as one of the lucky projects to be highlighted, appearing on the group page in October. The result was a boost of over £315 and we'd like to thank all who made a donation and to the admins of the group for including Western Prince.

Navigation through the A-End corridor is much easier with the treadplates back in place but the floor going down symbolises, and now hides, great progress below with power cables from the charging socket box to the BIS installed, control wiring through to both engine rooms along with several other little jobs done. And yes, we had the aching arms with cuts and bruises to boot, all good fun!

December saw the rewiring progress halted again as has often been the case. As saying goes one step forward, two steps back, or at least that's how it feels at times. A-end cab floor trunking was found to be rotten through, just as we were ready to pull all the wiring through to the cab bulkhead!

Found in the rotten conduit trunking were cab heater wires going into the conduit gland, another possibility for one of the numerous earth faults found since ripping it all apart, its amazing in some respects that D1041 lasted as long as it did electrically. Prince is not alone though, we're reliably informed that both D1013 and D1062 have had similar issues found in the past.

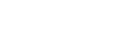

A End engineroom corridor showing one of the conduit junctions during pulling through (left) and the corridor with floor plating back in place at last

One of the many possible earth fault contenders!

Christmas Time

(Figuratively and Literally)

New polyrad cable has been ordered several times to progress with the rewire and this has been

possible as a result of the many kind donations which have been made. If you'd like to make a

donation yourself please see the Help D1041 page.

Even Princey got something for Christmas. When constructed it will be a good sturdy workbench fitted in the largely complete boiler room space at the centre of the loco. This will provide an integral work station and hopefully eliminate much of the constant clambering up and down the loco for a flat surface to repair parts and overhaul components. Also some BA tap sets for the stocking!

The bolier room area will realistically never be used for steam heating again. As well as being one more thing to potentially go wrong, the steam pipe is incomplete, having had parts removed over the years and much of the boiler control switch gear has been used for electrical reliability modifications to other areas.

After Christmas another gift came, this time from Jeff Targett and the WLA, a massive shout to them for a very generous donation of a 2 metre offcut of new galvanised steel trunking to replace the rotten sections at A-end of 1041.

Brand new Polyrad cable drums and the 2 metre galvanised trunking donated by the WLA

Brand new Polyrad cable drums and the 2 metre galvanised trunking donated by the WLA

The Year Ahead, 2014

Another year gone already, where does the time go? Still its been productive and progress made. By the end of 2014 the aim is to have the re-wire completed and the air system back together. We will also be piecing A-end back together with pipework, anciliary and auxiliary equipment once overhauled. The job list still to do is astronomical, so 41 wont be returning to service this year. But heres to continued progress.February saw progress on the very detailed bodywork restoration and critical structual repair work. B-end box sections and sand boxes being completely remade. Mr Martin Tottle is working his magic once again and was heard to say "It's literally going to be a brand new locomotive when we're finished".

Inside, the re-wire is picking up pace. Once the new trunking is fabricated for the floor, all the cables can be run into A-end cab and the floor put back down. Three more end to end cables remain to be run in, then it will be literally (just!) one cab to build and wire from scratch, the other cab to complete connecting up. And we shall hopefully see signs of electrical life from 41 for the first time properly in 10 years.

February, B-End - Drivers side cab floor support inserted (left) and another fabulous splash back gusset!

March, B-End - Drivers side cab re-attached to frames(!), something of a design flaw also found at A-End, and on the Driver's corner new webbing installed as the comprehensive rebuild continues

As well as further bodywork progress at B-End, March saw Matt traded Polyrad for welding wire to fabricate new radiator compartment floor drain pipes. With the wiring in place, the pipe and drain work complete, fitted and secured and the floor and pipework virtually immaculate, B-end floor plates could go back down.

B-End - Radiator compartment floor section with drain pipework being attached (left) and back in position.

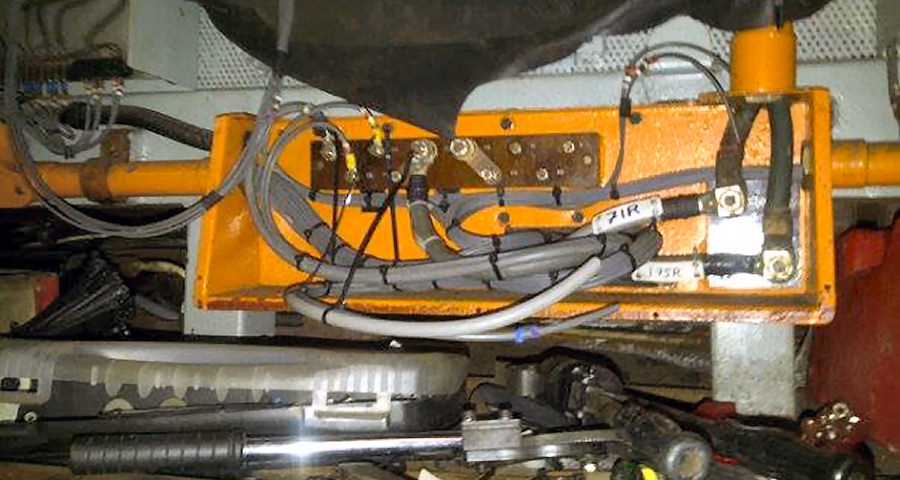

Early March saw another delivery with 50 meters of 35mm2 auxiliary cable for 1041s AVR circuit. After a bit of number crunching and scientific analysis, we identified that the end to end cables the thousands were originally wired with for the AVR's were way over specified, being of power cable gauge and size despite the tails from the terminal box to the AVR's being 2.5mm if that.

Cable 71/72R needs to be a maximum of 35mm2 and cable 76, which is just the balancing resistance between the two equalising coils, even in maximum fault condition if one AVR went completely short circuit and was offering no resistance, would need to be around 10mm2 at most, representing a significant saving on copper cabling.

Our calculations were thorough by necessity, taking into account volt drop per meter within the cable itself, ambient operating temperature and a fault condition exponential current spike, the AVR will still be the weakest part of the circuit and would fail way before the cable gets hot enough to suffer any damage.

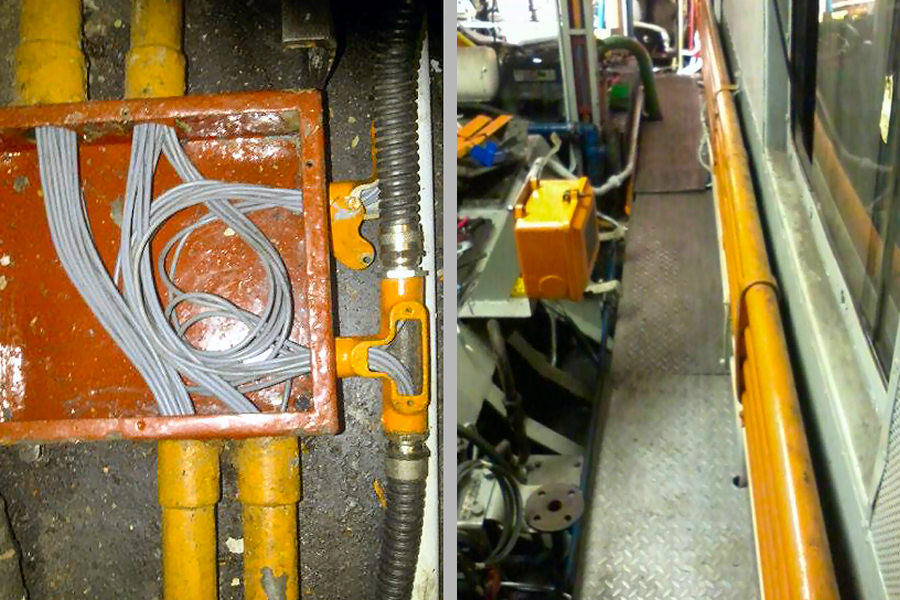

Pass-Goods Magnet Valve refurbished (left) and a view of the completed Cab to Cab wiring loom climbing up from floor level to travel along the inside of the loco

Main wiring junction box behind B-End headcode box now complete

Despite the Western Prince lending a hand with D9537 aka 'Eric' the D1041 project remained in focus. Matt managed to overhaul the Passenger/Goods changeover magnet valve whilst also engaged with Stephen and Alan looking at the electrical state of 'Eric'.

Along with this, the wiring within B-End nose was completed along with the end to end power cables (25 metres each) and the AVR wiring. The decision regarding the use of electronic or standard old style AVR's is still under investigation. Another milestone was achieved at the end of March with the cab to cab wiring finally completed, the huge lengths of cable now fed through and reaching both ends of the loco meaning that conduit lids can go back on and floors back down.

The sheer amount of wire, labels, measuring and cutting, not to mention the cost, meant the cab to cab would always be a massive time consuming task. So with the cables in the team are eager and have a renewed energy to get B-end cab finished and the second cubicle frame back onboard and fitted under the desk.

The Davenset rebuild and modifications are still ongoing, but other than that, the rest of the cable is in (with the exception of lighting circuits) and just waiting to run into A-end cab. Electrically its really coming together but also ongoing is the full air system overhaul, along with generally building the A-End back up with pipework and auxiliary components.

It is hoped from an electrical point of view, with some hard work, and well-constructed methodical progress, that we may see the Battery Isolating Switch closed and live testing commencing towards the end of 2014 or beginning of 2015. Before the A-End cab can be accessed the outstanding fabrication repairs to both the cab and desk will need to be finished including removal of the windscreens to replace structural metalwork compromised by excessive corrosion and water ingress issues.

The D1041 team would like to extend a huge thanks to everybody who has contributed, be they internally involved shareholders and engineers or those who have sent donations via the website. Thank you.

Martin Tottle and Matt Lindley

and humble apologies from the D1041 webmaster!