D1041 Progress Report:

Autumn/Winter 2011

There has been plenty going on since the last D1041 report and this roundup details where we're upto as of now and the plans for the immediate future.

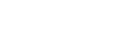

At B-end of the loco, plenty more new cable has been going in with a large amount of time spent fitting out as much of the internal wiring around the drivers desk as possible. This includes all the wiring for the driver's and secondman's warning lamps, the loco circuit breakers, instrument lighting, direction selector column, loco control push buttons (Engine Stop/Start, Tooth on tooth, Rear horn valve) as well as the loco cab switch panel and DSD circuitory.

The B-end wiring will then take a back seat until we get the end to end loom made up and fed through the loco to connect both desks up. Once this is installed, any remaining internal wiring can be added and we will be able to start terminating all cables at B-end, begin sequence and simulation testing, then finally tidy and tie up everything securely.

More cables going in around B-End cab

The more cable we've removed, the more apparent it has become just how desperately Prince's electrical systems needed this level of work. All of the original wiring has a rubber coating which, over time, becomes brittle and prone to failure, leaving bare wire exposed.

Many examples of cable failure have been found but one of the more extreme examples of this was discovered as we removed the loom thats feeds to the A-End compressor from the control box in the boiler room. A block and tackle had to be clamped onto the old cable loom to drag it out of the conduit as the motor cable insulation had weakened and evenutally blown to earth with a bang resulting in a mass of melted copper welded hard to the inside of the conduit.

With B-end cab progressing well, attention has now turned to the daunting task of stripping out and assessing A-end cab. The cab is now fully stripped out bare and we have already gone deeper with this cab than the other. The desk has unfortunately suffered just as much, if not more corrosion caused by water ingress as found at B-end. Initial assessment has revealed that the floor beneath the desk will require the entire secondman's side to be cut out and a new steel sheet welded in place. A new conduit box will need to be fabricated for the looms coming up from the BIS and davern set - the old box was corroded out of existance, just a hole in the floor. A-end will now have the remainder of the old unipren cable pulled out and a big stripping session will go ahead to get as much copper weighed in to go towards the 200m of power cable we need to install in the loco.

Almost fully stripped out A-end cab, to be rebuilt over the coming months - not a job for the faint hearted!

Ideally, dependant on funding, it is hoped that by the end of play 2012, the majority of the re-wire will be complete enabling testing proceedures to begin to ensure all is present and correct. This will only happen if we can raise the sufficient funds for the 95mm power cables. The smaller, but still costly, cable looms for the compressors and exhausters are now all fed into the loco and we hope to be able to continue ordering drums of control wire as we progress. A few months worth of work will now go into rebuilding A-end cab to the same standard as B-end.

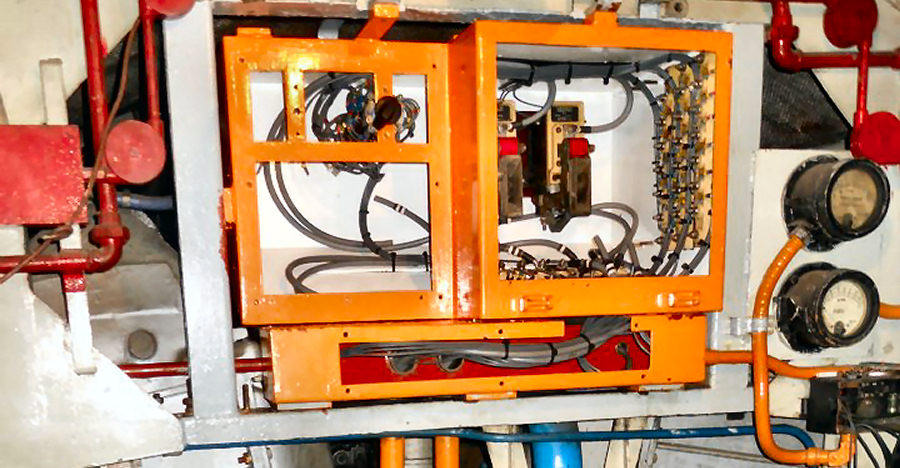

Two other electrical projects recently completed were the re-installation of the fully overhauled and re-wired dual brake control box in the boiler room. Having been stripped out and refurbished the unit was refitted, connected up to the loco and sequence tested. The Battery Isolation and Exhauster switching/fuse panel has been completely refurbished ready for returning to the loco in due course.

Refitted Dual Brake control box

A-End tranmission back in position

Refurbished BIS and Exhauster switch/fuse panel (front)

... and the rear view showing the component details

Away from the mass of electrical work other areas are also progressing. As you may have seen from the previous report, just before christmas the replacement transmission was fitted to A-end of D1041. The overhauled serck oil reservour tank, various bits of framework and testing of the dynostarter in A-end also took place in readiness for the transmission's return. The lift went smoothly and the Voith transmission has now been bolted down and torqued up. We can now start refitting peices of pipework around the transmission such as the large pipes that feed the cooler group. These will be needle gunned to the limit to find any possible weak spots that could develop leaks and cracks before painting and re-fitting.

At B-end, the cooler group has been disconnected ready for removal in the coming months. With the cooler group out of the loco we will be able to remove B-end dynostarter which needs a full overhaul including a blow through/dry out, deep clean, re-varnish and new brush gear. The B-end compressor can also then be reached easily, its condition assessed and any work carried out either in-situ or out of the loco if necessary. Easy access to the non-corridor side of this end of the loco will also be possible for cleaning and painting.

D1041 became rather notorious in the years before withdrawal from preservation traffic for problems with the reverser block on B-end transmission. The plan is to remove and test the block and, depending on what we find, fix the problem or swap it for the reverser block on the old A-end transmission. Whichever happens the incoming block will be tested and overhauled as necessary. B-end also saw the re-fitting of the oil and fuel priming pumps which were fully overhauled by Chris baily, alongside pumps and machines from BTH Type I, D8233. Chris has kindly volunteered to overhaul all of D1041s motors to the same high standard (Thanks Chris!).

The refurbished oil priming pump was connected up to B-end engine which was decompressed and barred round with ease, the priming pump was then run using an external power supply and an oil pressure reading was achieved on B engine for the first time in 7 years. This will be done at regular intervals to keep the engine well lubricated.

Oil pressure reading on B-end engine. First time in 7 years

This year we hope to get the majority of the bodywork repairs finished. Once the resident class 14 is returned to service this year, a few more hands should be available to do the re-fabrication work required on the 'B' front end and, towards the end of the year, hopefully make a start on the engine rebuild for A-end.

Plenty to keep us busy this year, but also plenty of excellent progress being made. If you feel you can contribute to the cause by making a donation towards buying the remaining cable needed (of which there is a fair bit) then please take a moment to view the details on our donations page.

Thanks for taking the time to have a look at how things are progressing, further updates will be posted throughout the year.

Heres to a prosperous 2012 for Western Prince!

Regards, Matt Lindley