D1041 Progress Report:

30th Septemer 2011

Firstly, apologies for not having had an update on the project, all of my efforts have been going into working on Prince and work reports have come second, I will be doing my best to supply a regular newsflow in the coming months.

Externally D1041 looks much as it did six months ago and so it is often assumed nothing much has been done. Seeing the South end cab in the shed with gutted front end and corroded bodywork people tend to inquire "no further then?" - However, on the contrary, far from it!

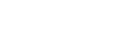

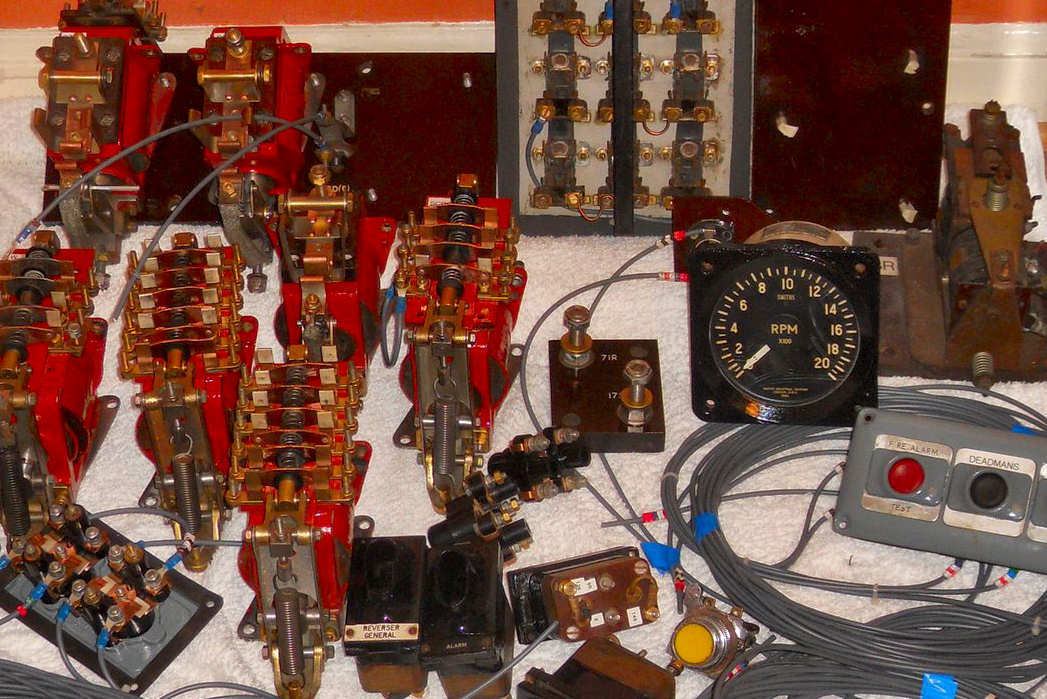

B End cublicle 4 during dismantling, Aug 2010

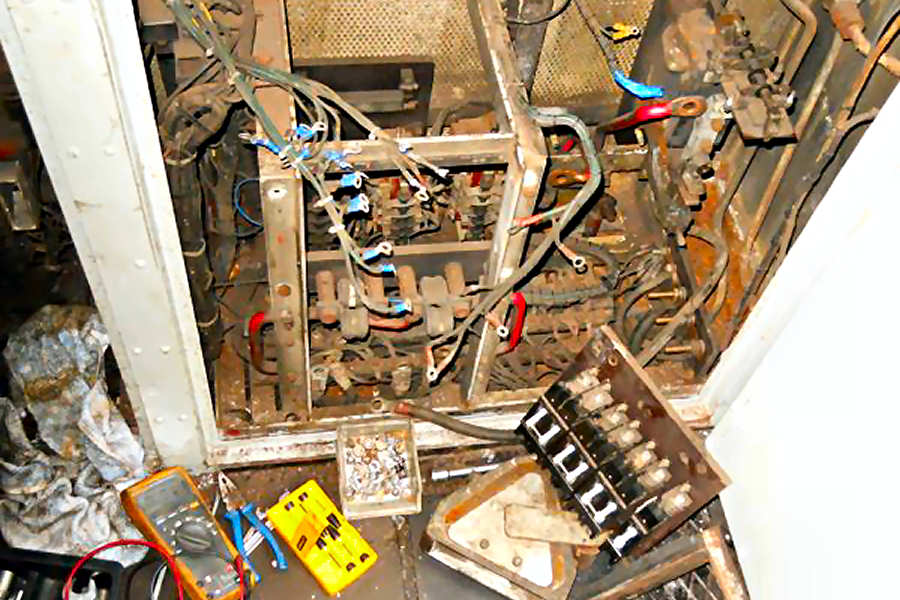

Refurbished and back in place, Sept 2011

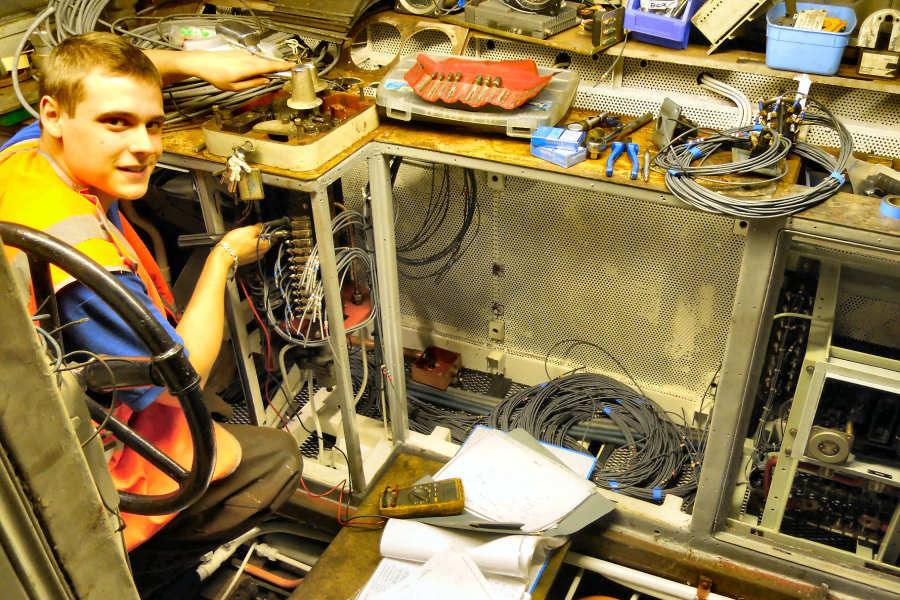

Work has continued steadily both at Bury and at 'BREL Denton' on refurbishing electrical cubicles, relays and switches along with removal of the old rubber coated cables, replaced and rewired completely with new 'Polyrad'. The electrics really were in desperate need of attention and had suffered further being stored out of use for 7 years or so, but I'm pleased to say I'm easily a third of the way there now.

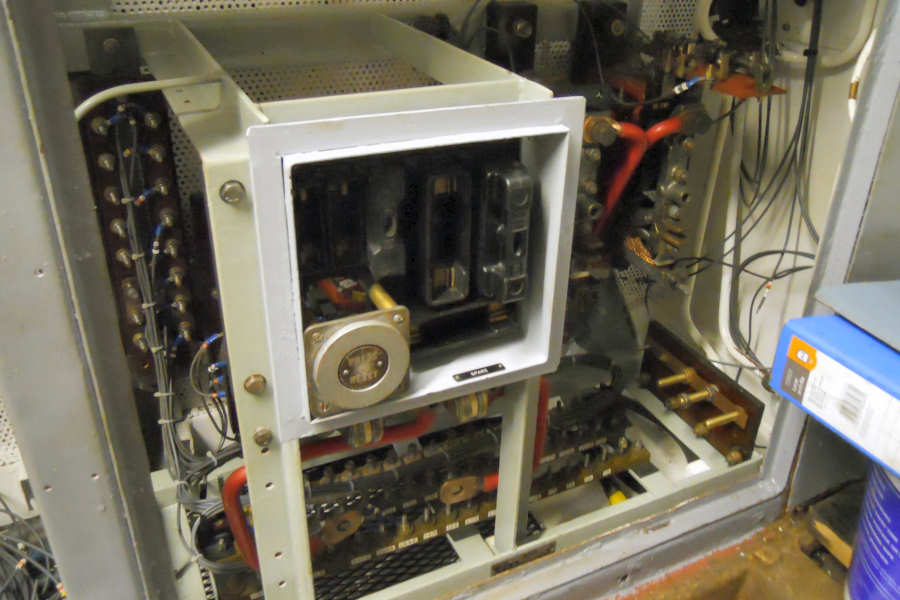

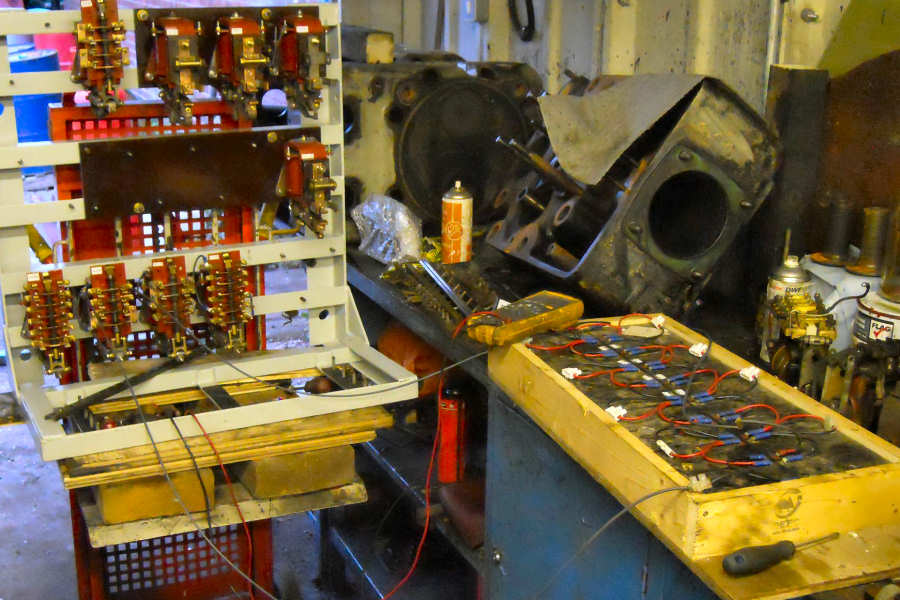

B-end (south end) of the loco is largely done in terms of the control looms that run from the desk to the transmission, engine, auxillaries etc as far as the fuel lift pumps in the boiler room. The cab and desk, which was stripped out to virtually a hollow shell is now well on its way to being complete again and is looking nice. One of the two control cubicle frames for B-end desk is now back in the loco, with the second being wired together.

B End cab stripped out, May 2011

Matt adjusting controller travel, Sept 2011

Electrical control switchgear refurbished as new, June 2011

Cubicle re-build and testing

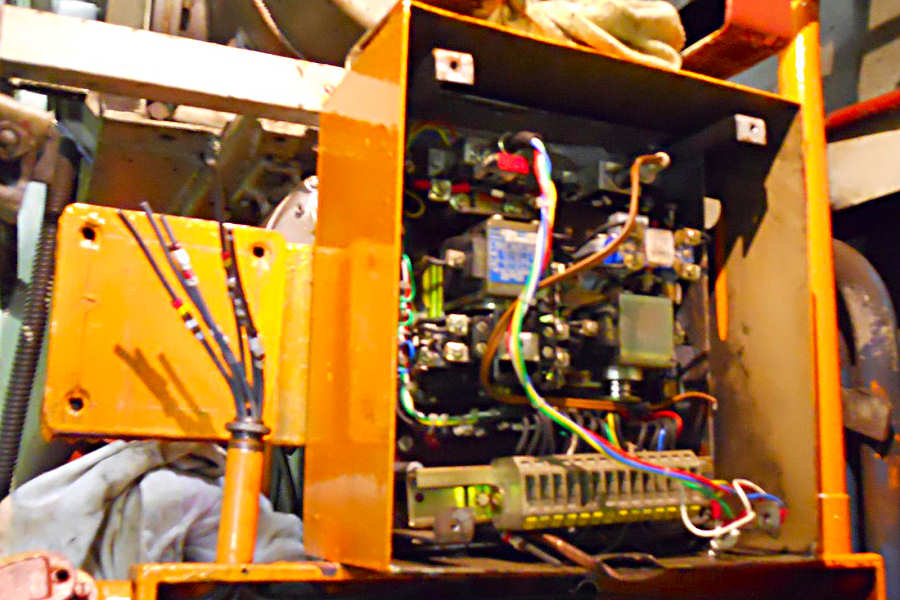

Moving away from the cab, I have also been working on the brake frame electrics. The Dual brake control box has been removed from the "V" at the boiler room side of B-end engine. Once stripped out, repairs have been made as necessary then the compressor contacts and terminal rails rebuilt. Once painted, a day or so of wiring and this will be good as new ready to go back in. The B-end pre-heater control box and junction boxes have been refurbished along with new looms for the timing magnet valves and various governors in the boiler room.

B End pre-heat control box

B-End electrical junction box

At the A-end, Brian Bowman has been taking the desk apart and, with B-end almost done, the wiring layout is much better understood and should prove quicker and easier to complete. I have been compiling CAD drawings and schematics over the months and now have a full cable schedule listing every wire and where it runs from/to. The A-end nose also has some severe corrosion, equal to if not worse than B-end, which will need treatment and correction as well as preventive solutions against water ingress.

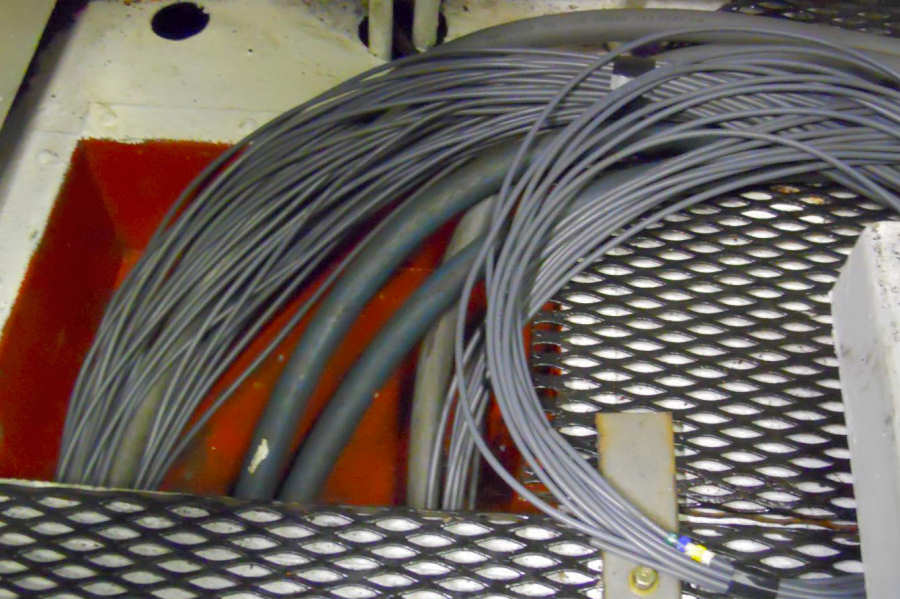

The other remaining wiring project is the End-to-End cables. Despite my initial concerns I'm confident this will actually be simpler than the maze of conduits in B-end, that said, the loom consists of 80+ wires and the 4 large power cables which loop the two AVRs in series, the start contacts at both ends and connect battery negative at both ends. The finished loom will be around 84feet long, taking into account routing along the loco and desks. A sizable amount of cable required but once made up, with a few pairs of hands feeding it down the conduits, it shouldn't be quite so bad as first thought.

New looms emerge from B-end Cab floor

B-End Dynostarter brushgear damage

Everything with an electrical connection is being inspected and assessed as the new cables make their way around the locomotive, with all items either renovated in place or noted as requiring removal for attention. The brush gear on the B-end dynostarter appears to have some damage and we are considering removing both dynostarters with a view to giving them a deep clean and re-varnish as well as new brush gear if necessary.

Our dedicated Maybach container has recently arrived at Castlecroft and will be emptied, refitted with a workbench and storage solutions for items both renovated and awaiting renovation. This will free up working space inside the loco and give us a secure place to keep all things 'Prince' related.

As you have seen there has been a great deal of progress made, still plenty of work to complete though! A summary of the larger tasks still outstanding:

- A-end engine to be fully rebuilt

- A-end transmission, cooler group and auxillaries to re-fit

- Exhausters, oil/fuel priming pumps to be sent away for overhaul

- Remove B-end cooler group to access non-corridor side inc conduits, compressor and B reverser

- A-end cab to gut, repair, rewire and rebuild

- Cubicles to overhaul

- BIS & Davenset to overhaul

- Loco lift for underside exam, service bogies and tyre turning

Last, but by no means least, I would like to thank everyone who has helped with the project so far and especially to those of you who have made donations to the cause.